Pavement stabilisation, recycling and rehabilitation services

Designing carbon neutral pavement solutions.

Hiway’s pavement stabilisation and recycling solutions deliver better performance and lower carbon outcomes compared to traditional methods. From initial concept, through to full solution design optimisation and installation across all levels of a pavement, Hiway’s services are tailored for maximum benefit for the client.

Pavement design and project management

Recycling

Aggregate modification

Conditioning

Pavement design and project management

Hiway is the only specialist pavement stabilisation, construction and rehabilitation contractor in Australasia providing comprehensive in-house design and project management from inception to completion.

The team’s expertise spans pavement design, foam bitumen, pavement stabilisation, rehabilitation, contamination remediation, and heavy duty/overlay pavement solutions, including airport and port applications, highway pavements, and optimisation of life-cycle costs for low and high volume roads. They also provide pavement investigation, materials classification, sampling, subgrade analysis, design optimisation and carbon assessment and calculation of pavement emissions. (See our Tairawhiti Emergency Work feature project as a prime example.) The calculation of carbon emissions is undertaken in accordance with ISO 14040/14044 and BS EN 17472.

Recycling

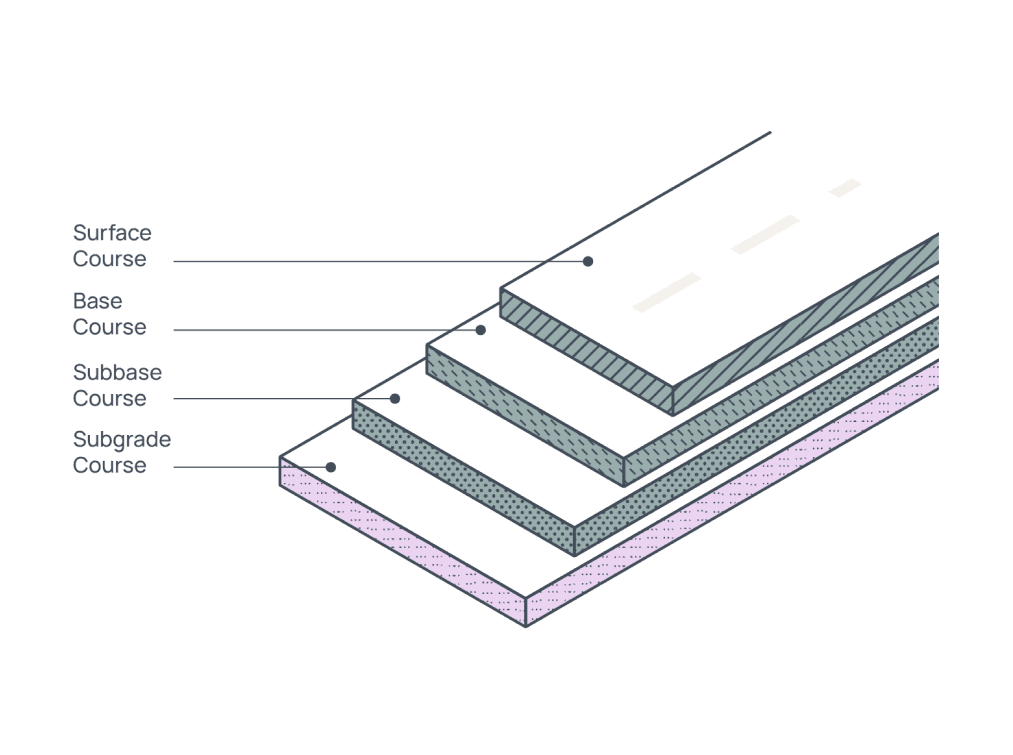

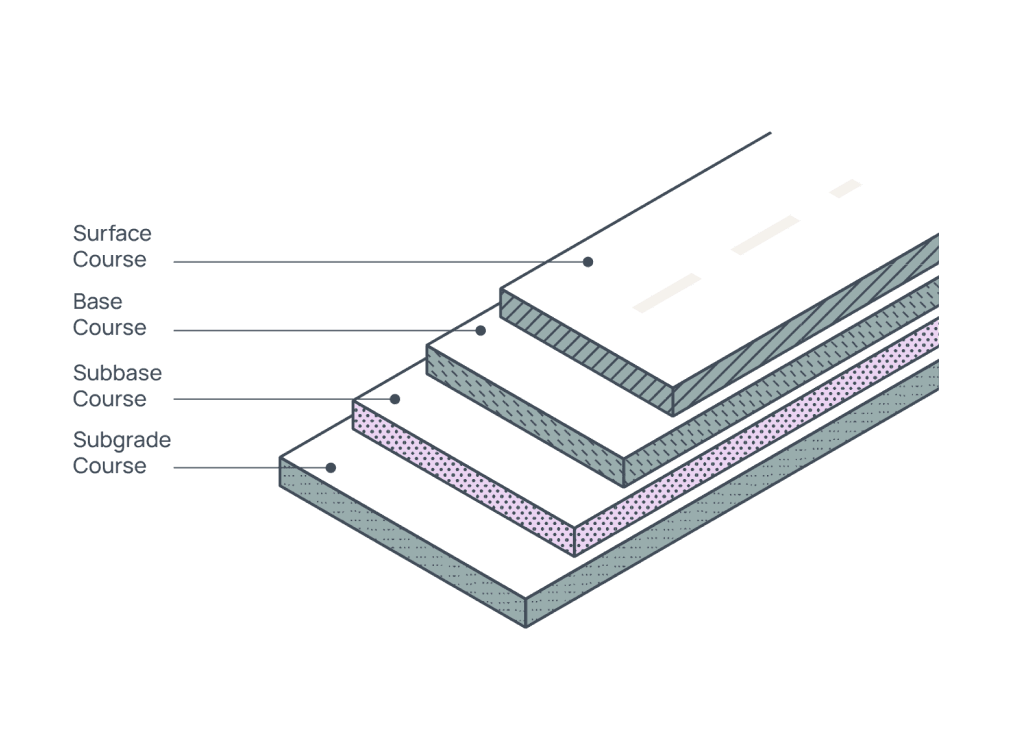

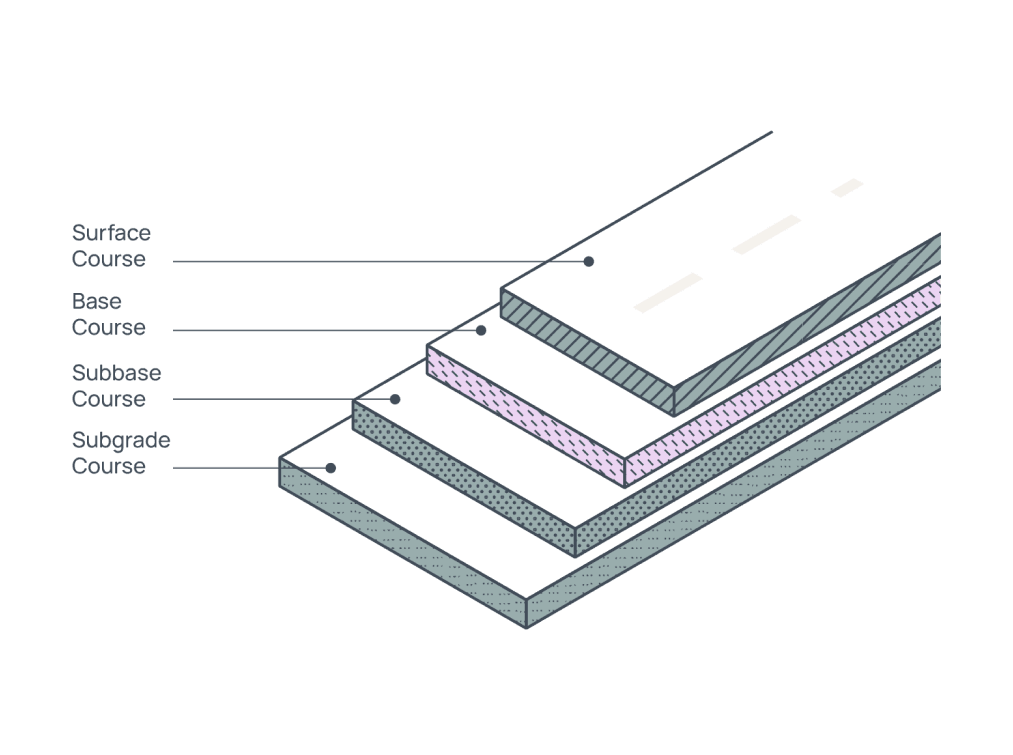

Subgrade Recycling & Fill Drying

Hiway’s subgrade recycling, reuse and fill drying services enable significantly faster construction over traditional discing & air drying or importation of costly materials to improve strength. The process is environmentally sustainable, cost effective and provides reuse and improvement of exiting subgrade materials to accelerate construction programs and extend earthworks windows. With extensive experience with all New Zealand, Australian and Pacific soil types, the design team offers expert advice and laboratory testing to confirm the natural versus post-treatment strength of subgrade material.

By using specialised binders, aggregate requirements can be cut by more than 50%, reducing the amount of excavation needed during construction.

Hiway also pioneered fill drying in New Zealand. With specially designed plant, delivering chemical modification of fills and wet of optimum soils, it can radically improve load bearing properties and enable its immediate use and earthworks to continue in adverse conditions. Fill drying also reduces the requirements for cut to waste, enabling greater reuse of the existing on-site materials and reducing the need for imported aggregate. Hiway is actively developing its use with road authorities and land developers across Australasia.

It has significant benefits for subdivision land developers where the completion of earthworks to tight construction programmes is critical to section sales. Fill drying is also well suited to infrastructure projects where earthworks completion is critical to the civil works construction programme.

APPLICATIONS

Construction of new and existing pavements

Moisture conditioning of earthworks for residential subdivisions

Fill drying for extension of earthworks construction seasons

Recycling and reuse of subgrades for civil, industrial and commercial developments, and infrastructure projects

BENEFITS

Significantly improved in-situ subgrade stability

Subgrade strength gains of up to 20 times

Cost savings due to reduced requirement for imported aggregates, fewer transport costs and faster construction time

Reduces risk of costly subgrade pavement failures

A robust, durable platform for aggregate construction

Substantially reduces moisture susceptibility

Creates a more uniform pavement layer

Dries large volumes of water-logged soil instantly

Can be carried out in poor weather conditions

Reduces down-time by enabling earthworks to continue immediately after wet weather

May enable reduced pavement thickness, providing significant cost savings

Recycling forms a soil particle and moisture barrier that protects overlying aggregate layers from upward migration of plastic fines

Subbase Recycling

Subbase recycling offers a savvy, eco-friendly approach to both new pavement construction and existing pavement rehabilitation. By reusing materials, it slashes the demand for premium aggregates and conserves high-quality resources, all while delivering robust performance.

APPLICATIONS

Recycling aggregates for new pavements

Remediation of failed pavements

Utilising local marginal aggregates previously unsuitable for road construction

BENEFITS

Strengthens and enhances performance of marginal aggregates.

More cost-effective than premium alternatives

Rapid placement, with a single crew recycling up to 1km of two-lane road per day.

Durable surface, requiring less maintenance than premium options.

Drastically reduces need for pavement material replacement.

Faster, easier final trimming and surface prep

Minimises imported material, cutting costs and carbon footprint.

Swift turnaround minimises public inconvenience.

Basecourse Recycling

Hiway revolutionised basecourse recycling in Australasia, leveraging proprietary binders to forge pavements with superior strength, performance, and extended lifespan. Through basecourse recycling, in-situ or imported materials are enhanced with tailored binders, specialty blends, polymers, or foamed bitumen, delivering swift rejuvenation for aged pavements at a fraction of the cost.

APPLICATIONS

Remediation of failed pavements

Strengthening existing pavements

New pavement construction

Maintenance patching

Area-wide pavement treatments

Seal smoothing.

Enhancing ride quality

BENEFITS

More cost effective than traditional methodologies.

Conserves diminishing aggregate resources.

Significantly reduces or eliminates excavation volumes.

Quick turn-around process minimises inconvenience to the public.

Can be carried out in unfavourable weather conditions.

Can be trafficked almost immediately.

Reduced maintenance requirements and whole-of-life costs.

Significantly improved resistance to moisture and pumping of fines.

No risk of shrinkage cracking.

Foamed Bitumen Recycling

Foamed Bitumen Recycling (FBR) delivers a resilient pavement solution, vital for combating the growing impact of climate-induced wet weather events. It offers a sustainable fix for aging pavements or those needing reinforcement against heavier loads. Cost-effective and eco-friendly, FBR outshines traditional methods, especially in constrained environments where major overlays aren't feasible.

The process is swift, bypassing the need for new aggregates, and the resulting pavement is ready for traffic almost immediately. FBR's adaptability spans the globe, from Australia to Europe.

FBR pavements can be laid using cutting-edge in-situ equipment or mobile foamed plants.

APPLICATIONS

Remediation of failed pavements

Strengthening existing pavements

New pavement construction

Maintenance patching

Area-wide pavement treatments

BENEFITS

Cost-effective alternative to traditional methods

Cheaper than deep lift asphalt

Produces durable, resilient flexible pavement akin to asphalt.

Effectively mitigates freeze-thaw pavement deterioration.

Preserves aggregate resources.

Minimises excavation volumes.

Swift turnaround minimises public inconvenience.

Works in unfavourable weather conditions

Ready for traffic almost immediately

Lowers maintenance and life cycle costs.

Enhanced resistance to moisture and fines pumping

Eliminates risk of shrinkage cracking

Plant-mixed Foam Bitumen

Plant Mixed Foam Bitumen (PMFB) material blends recycled or newly crushed rock aggregates, bitumen, and stabilizing agents like lime, cement, fly ash, and water, creating a robust recycled pavement material. Highly resilient, especially in flood-prone areas, PMFB requires less bitumen than full-depth asphalt while providing comparable strength, making it ideal for base course pavement layers.

With nearly 40 years of proven success globally, PMFB base offers a dependable, structurally sound pavement. Hiway leads the industry by incorporating alternative waste streams and existing road materials into unique mixed designs, reducing the carbon footprint and secondary binder use. Committed to a zero-industry carbon footprint, Hiway provides a cost-effective, environmentally superior solution for pavement construction, rehabilitation, and maintenance.

APPLICATIONS

New pavement construction

Pavement rehabilitation

Maintenance patching materials production

Stockpiling for extended working times.

BENEFITS

Cost-effective alternative to full-depth asphalt

Highly resilient, even in flood-prone areas

Longer working time compared to alternatives.

Creates strong, durable, and flexible pavement layer

Aggregate modification

In New Zealand and Australia, pavements traditionally rely on premium imported aggregates, driving up costs due to production, sourcing, and transportation challenges. However, aggregate modification offers a swift, cost-effective solution, reducing reliance on new premium materials which may not be readily available and provides for strengthening of existing pavements with minimal disruption.

Hiway aggregate modification elevates marginal quality aggregates to match or surpass premium counterparts in structural integrity and performance.

APPLICATIONS

Pavement Construction: Enhance subgrade stability and workability for durable pavements.

Subdivisions: Reinforce building foundations and treat weak plastic soils.

Embankments: Fortify against erosion, settling, and slope failure.

BENEFITS

Cut construction and maintenance costs, saving time.

Utilisation of poor-quality local aggregates that would normally only be suitable as a fill material.

Boost load-bearing capacity, providing a solid, stable working platform.

Conditioning

Moisture Conditioning

Moisture conditioning swiftly provides for drying of large volumes of wet of optimum soils or equally enhances moisture in dry soils, ensuring compaction compliance and facilitating immediate earthwork continuation. Compared to conventional methods, moisture adjustment can save up to 50% of water and yield more consistent results, especially beneficial in water-scarce regions.

APPLICATIONS

New pavement construction

Moisture conditioning for residential, rail, civil, and infrastructure earthworks

Moisture conditioning for industrial and commercial development earthworks

Rehabilitation of existing pavements

BENEFITS

Reduced transport costs and faster construction

Substantial reduction in moisture susceptibility and plasticity

Instant drying of water-logged soil

Enhanced load-bearing capacity of dry soils with added moisture

All-weather operation capability

Contamination Remediation

The issue of contaminated ground poses a significant challenge across Australia and New Zealand, with the leaching of chemicals threatening groundwater and watercourses, and disrupting our delicate ecological balance. Hiway offers a range of innovative solutions designed to address this pressing concern.

Our expertise lies in chemically fixating and encapsulating materials, effectively preventing leaching and eliminating the need for costly removal to landfills. This approach not only reduces financial and carbon footprints but also preserves landfill capacity for more suitable materials.

We specialise in addressing a wide array of contaminants, including hydrocarbons, heavy metals, and chemical pollutants. By mixing binders with contaminated materials, we produce a product with minimal environmental impact. Furthermore, our solidification and stabilisation methods enable the reuse of treated soil as engineered fill.

APPLICATIONS

Contaminated site remediation

Activities in areas with high water tables, including permeability barriers.

Remediation of mine tailing contamination

Soil recycling initiatives

Prevention of ground leaching and watercourse contaminationDe-sludging of ponds and watercourses

Cleanup of industrial contamination

BENEFITS

Cost reduction in waste disposal

Decreased project costs and timeframes facilitated by specialist equipment that swiftly treats contaminated areas.

Reuse of contaminated waste as engineered material, extending its useful life instead of disposal

Minimised impact on dwindling landfill capacity.